Large Flow Sanitary Volute Centrifugal Pump

Sanitary centrifugal pump

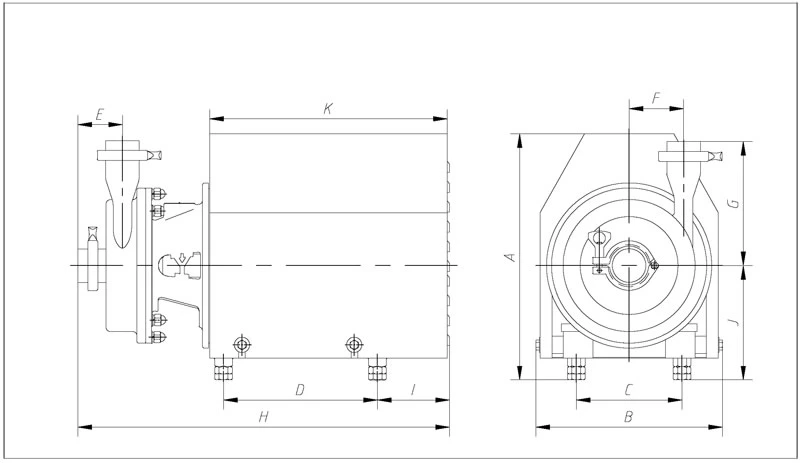

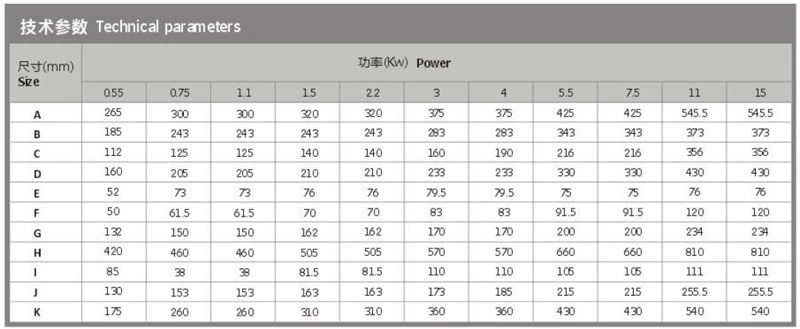

Technical Parameters:

| Specification | 1T-500T,0.55KW-75KW |

| Material | SUS304, SUS316L (in terms of material selection, the pump body, pump cover, impeller and other parts that come into contact with the material are made of SUS316L or SUS304 stainless steel) |

| standard | FROM, SMS |

| impeller | Open impeller, no dead corners left |

| Working conditions | Sanitary centrifugal pumps are used for high and low liquid level and horizontal transportation, and are not self-priming. (Self-priming pumps are used for self-priming pumps) |

| Surface treatment | The wetted parts are polished, the rest are matte or sandblasted |

| Maximum inlet pressure | 0.5MPa |

| Temperature range | -10℃ to 140℃ (EPDM) |

| Flushable mechanical seal | Water pressure: Maximum 0.1MPa Water volume: 0.25-0.5L/min |

Motor:

1. According to the configuration, it mainly adopts the high-efficiency M2BAX three-phase AC motor of the "ABB" brand, designed and manufactured according to the International Electrotechnical Commission IEC6OO34.IE60072 standard, and meets the requirements of the European Community CE marking

. 2. Explosion-proof motors can be selected to meet the needs of different occasions. 3.

Superior electrical performance, low noise, low vibration, the standard design protection level of the motor is IP55, and the insulation level is F.

4. Frequency: 50Hz/60Hz

5. Working mode: continuous (SI)

6. Speed: The speed of the standard pump is 2900r/min

Pump inlet and outlet connection

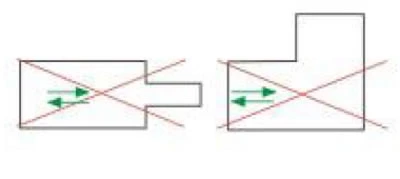

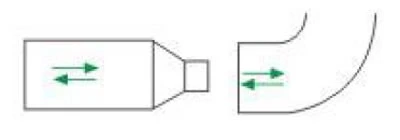

Liquid will lose energy in the pipeline, which can be divided into along-the-way loss and local resistance loss. The smoother the inside of the pipe, the smaller the along-the-way loss. The fewer bends and the smaller the change in pipe diameter, the smaller the local resistance loss. Therefore, try not to use rough pipe connections, and do not use sudden changes in pipe connections.

Wrong connection pipe

Correct connection pipe

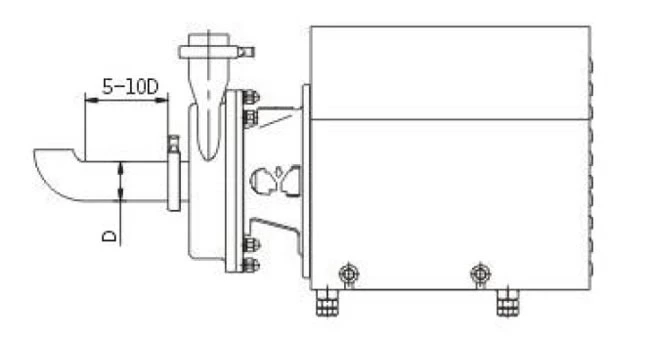

Pipe diameter and connection distance

When the pump is running at a low flow rate, the efficiency is very low, and the energy consumed causes the liquid temperature to rise sharply. When the pump is running at a low flow rate, the backflow through the impeller gap increases, causing the pump pressure pulsation, vibration, noise and other hazards to increase. Therefore, the inlet diameter of the connected pipe should not be less than the designed inlet diameter. In order to ensure more stable operation of the pump, a straight pipe needs to be connected in front of the pump inlet, with a length of about 5-10 times the pipe diameter

Pipe inlet connection distance

Sanitary centrifugal pump model description

Example