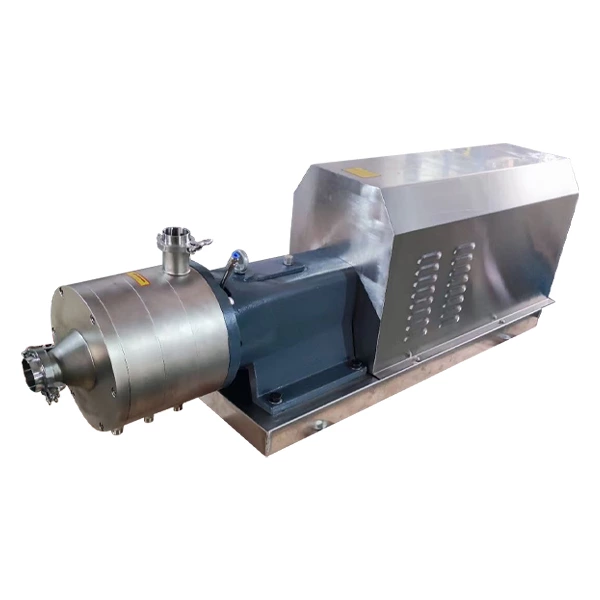

Single Stage Emulsification Pump

Sanitary emulsification pump

Product Introduction

The pipeline high shear homogenizing pump is a high-performance equipment used for continuous production or cyclic processing of fine materials. In a narrow cavity, 1-3 sets of dual-bite two-layer stators and rotors are installed. The material is treated with equal shear probability in an instant through the working cavity, which can narrow the particle size range and improve the uniformity. Online processing eliminates the quality difference between batches and maintains constant quality. The stator and rotor module combination is suitable for the needs of different working conditions. It is designed for online metering and mixing, intensive production, and has short-distance, low-lift conveying functions.

The pipeline single-stage emulsification pump is a device that efficiently, quickly and evenly transfers one or more phases (liquid, solid, gas) into another immiscible continuous phase (usually liquid). Under normal circumstances, the phases are immiscible. When external energy is input, the two materials are reorganized into a uniform phase. Due to the high tangential speed generated by the high-speed rotation of the rotor and the strong kinetic energy brought by the high-frequency mechanical effect, the pipeline single-stage emulsification pump causes the material to be subjected to strong mechanical and hydraulic shearing, centrifugal extrusion, liquid layer friction, impact tearing and turbulence in the narrow gap between the stator and rotor, forming suspension (solid/liquid), emulsion (liquid/liquid) and foam (gas/liquid). The horizontal pipeline single-stage emulsification pump allows the immiscible solid phase, liquid phase and gas phase to be instantly and evenly dispersed and emulsified under the combined action of the corresponding mature process and appropriate additives. After the reciprocating high-frequency emulsification pump, a stable high-quality product is finally obtained.