- Sanitary Pumps

-

Sanitary Valves

- Sanitary Butterfly Valve

- Sanitary Ball Valve

- Sanitary Check Valve

- Sanitary Diverter Valve

- Sanitary Diaphragm Valve

- Sanitary Sampling Valve

- Angle Seat Valve

- Sanitary Safety Valve

- Sanitary Constant Pressure Valve/Back Pressure Valve

- Sanitary Plug Valve

- Sanitary CPM Valve

- Sanitary Level Gauge

- Sanitary Tank Bottom Valve

- Sanitary Accessories

- Sanitary Tank Accessories

- Stainless Steel Pipe Fittings

- Industrial Valves

- Stainless Steel Tank

- Food Grade Sealing Ring

Sanitary Flexible Impeller Pump

- Place of Origin::

- Wenzhou, China

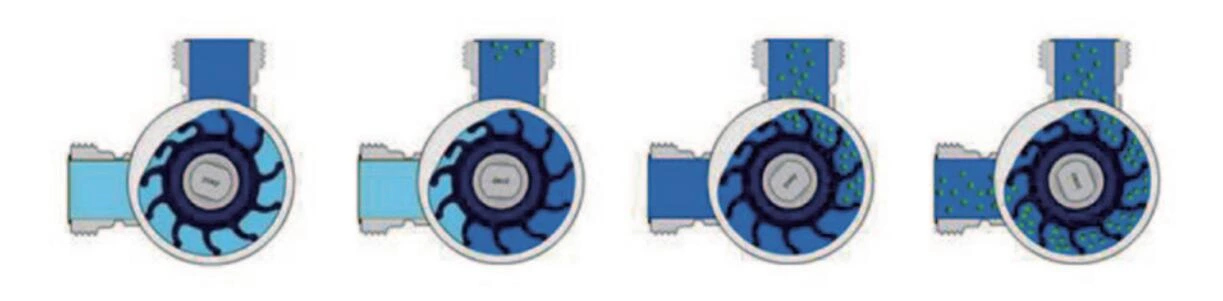

How it works

① There is an eccentric block in the pump chamber. When the flexible blades leave the eccentric block, the volume between the blades continues to increase, creating a vacuum, which allows the liquid to be continuously sucked into the inlet of the pump chamber.

② When the flexible blades rotate, the liquid is brought from the suction part of the pump chamber to the discharge part.

③ When the flexible blade contacts the eccentric bump again, it bends and is accompanied by a squeezing action, so that the liquid is discharged from the pump chamber uninterruptedly and without pulsation, thus completing the whole process of suction and discharge.

Technical advantages

1. Strong self-priming force, perfect structural principle, self-priming up to 5 meters.

2. Short self-priming time, instant self-priming within 5 meters, completed in 2-3 seconds.

3. Simple structure and easy maintenance. No professional guidance is required and the pump pipeline does not need to be dismantled for maintenance.

4. Buy a pump once and use it for life, with few wearing parts.

5. Small size and takes up little space for on-site equipment.

6. High efficiency with large flow rate, minimum power and most energy-saving under the same flow rate.

7. Noise-free indoor installation

8. The viscosity of the conveying medium can reach 5000 centipoise

Features

1. Small size, large flow - Generally speaking, compared with competitive pumps, it has the smallest volume at the same flow rate, which is easy to install and move.

2. Instantaneous and completely self-priming - no additional devices are required, no liquid replenishment is required before starting, and the suction range can reach five meters

3. The pump body is made of stainless steel precision casting, and all the metal parts passing through the flow are made of stainless steel (1Cr18Ni9Ti)

4. It can transport gas-containing liquid and foam liquid without air blockage.

5. Can transport medium containing suspended soft and hard particles

6. The gentle movement of the rotor does not damage shear-sensitive media, such as papermaking dispersants.

7. Beautiful appearance, durable and easy maintenance